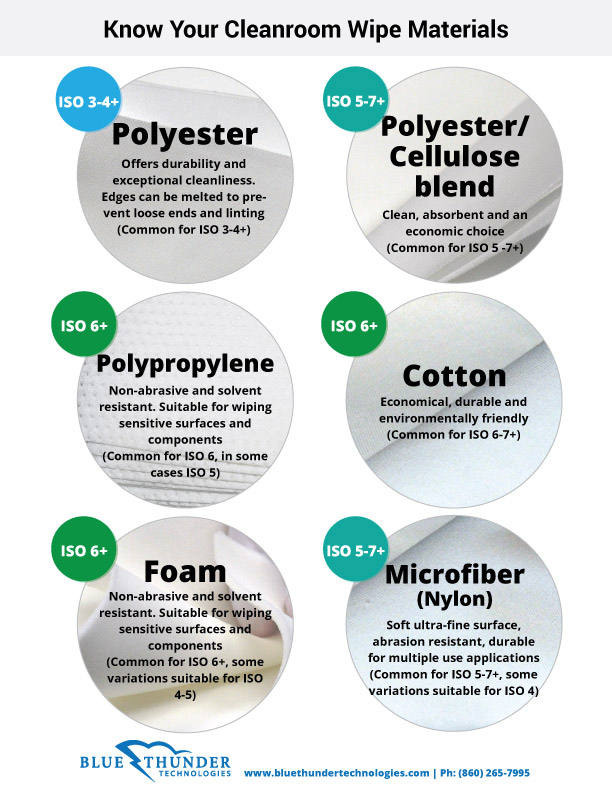

Know Your Cleanroom Wipe Materials

A variety of factors can influence the cleanliness of a wipe. From raw material to a finished product, the wipe will undergo numerous steps that influence and determine its cleanroom compatibility range. Examples include cleaning, scouring, cutting, packaging as well as the manufacturing facility that wipes are processed in. Before any of that takes place, perhaps the most important factor is the cleanroom wipe material itself - with each substrate offering unique benefits.

Polyester, Nonwoven Poly-cellulose, Polypropylene, Cotton, Foam, and Microfiber each offer unique wiping benefits.

View, print, or download the Cleanroom Wipe Materials Chart

Polyester

Offers durability and exceptional cleanliness. Edges can be melted to prevent loose ends and linting. Additional measures can be taken to further enhance cleanliness such as washing, processing, and packaging the wipes in a cleanroom. It can be presaturated with a variety of solvents, sterilized, and cut to any size. Common for ISO 3-4+ (Class 1-10) Cleanrooms

Polyester/Cellulose blends

Polyester/cellulose blends or nonwoven wipes can be engineered to meet unique requirements. Polyester/Cellulose blends are clean, absorbent and an economic choice. Like polyester wipes, this material can be cleanroom processed to further enhance cleanliness. It can be presaturated with a variety of solvents, sterilized, and cut to any size. Common for ISO 5-7+ (Class 100-10,000) Cleanrooms

Polypropylene

Polypropylene is soft, non-abrasive and solvent resistant. Suitable for wiping sensitive surfaces and components. Polypropylene can be cleanroom processed and washed to further enhance cleanliness. It can be presaturated with a variety of solvents, sterilized, and cut to any size. Common for ISO 6 (Class 1000), in some cases ISO 5 (Class 100) Cleanrooms

Cotton

Economical, durable and environmentally friendly. (Common for ISO 6-7+)

Foam

Non-abrasive and solvent resistant. Suitable for wiping sensitive surfaces and components such as optics and printheads. (Common for ISO 6+, some variations suitable for ISO 4-5)

Microfiber (Nylon)

Soft ultra-fine surface, abrasion resistant, durable for wiping a variety of surfaces. (Common for ISO 5-7+, some variations suitable for ISO 4)