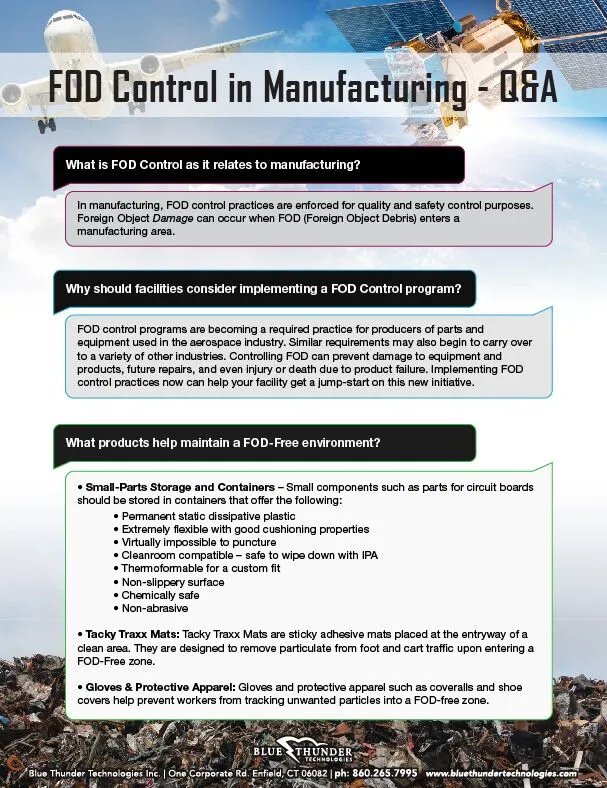

FOD Control in Manufacturing - Q&A

What is FOD Control as it relates to manufacturing?

In manufacturing, FOD control practices are enforced for quality and safety control purposes. Foreign Object Damage can occur when FOD (Foreign Object Debris) enters a manufacturing area.

Why should facilities consider implementing a FOD Control program?

FOD control programs are becoming a required practice for producers of parts and equipment used in the aerospace industry. Similar requirements may also begin to carry over to a variety of other industries. Controlling FOD can prevent damage to equipment and products, future repairs, and even injury or death due to product failure. Implementing FOD control practices now can help your facility get a jump-start on this new initiative.

What products help maintain a FOD-Free environment?

- FOD-Free Storage and Containers – Small components such as parts for circuit boards should be stored in containers that offer the following:

- Permanent static dissipative plastic

- Extremely flexible with good cushioning properties

- Virtually impossible to puncture

- Cleanroom compatible – safe to wipe down with IPA

- Thermoformable for a custom fit

- Non-slippery surface

- Chemically safe

- Non-abrasive

- Tacky Traxx Mats: Tacky Traxx Mats are sticky adhesive mats placed at the entryway of a clean area. They are designed to remove particulate from foot and cart traffic upon entering a FOD-Free zone.

- Gloves & Protective Apparel: Gloves and protective apparel such as coveralls and shoe covers help prevent workers from tracking unwanted particles into a FOD-free zone.